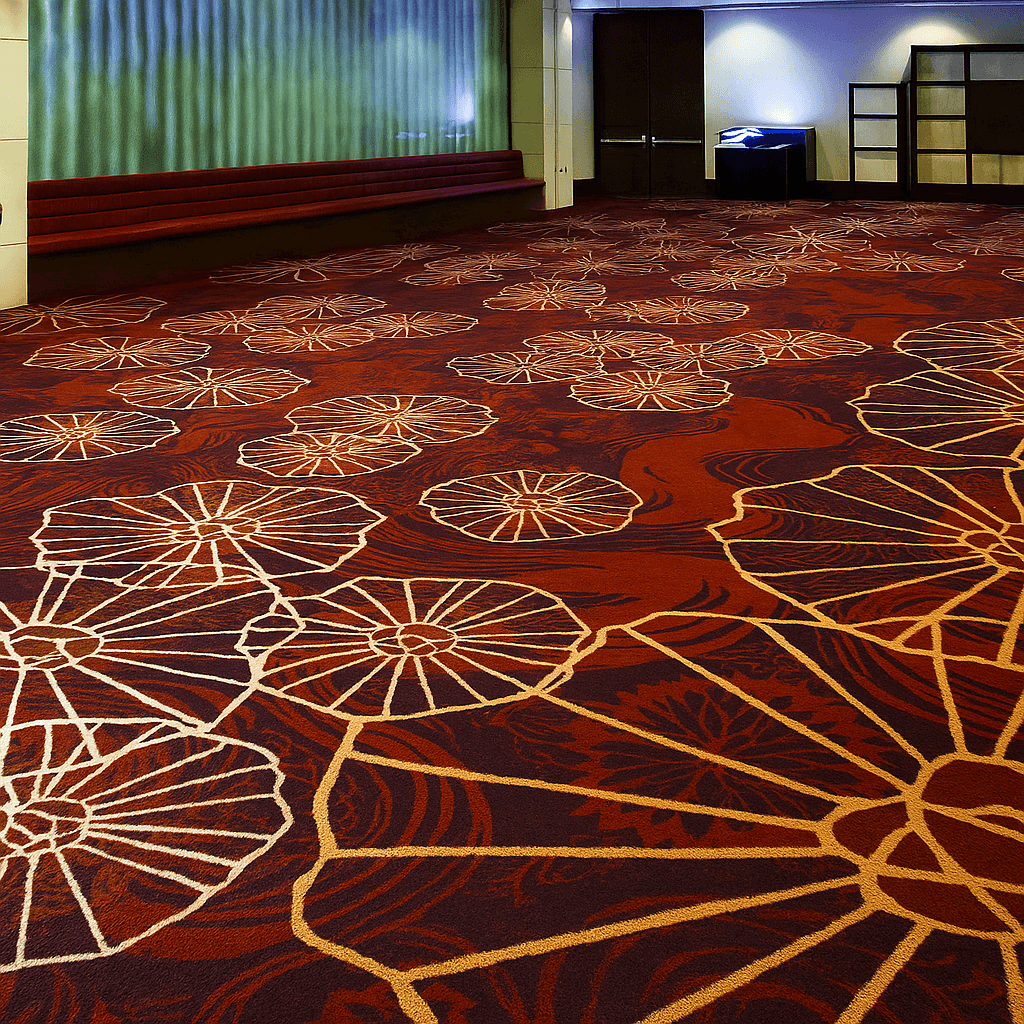

AXMINISTER 7X7

SPECIFICATIONS

| Function | Room |

| Construction | A genuine Woven Axminster |

| Pile Content | 80% Wool, 20% nylon |

| Yarn Count | R740/2 |

| Pitch | 7/inch(27.56/dm) |

| Rows/inch(Rows/Dm) | 7/inch(27.56/dm) |

| Tufted Density | 49/inch²(759.55/dm²) |

| Total Pile Weight | 1131g/m² |

| Pile Height Above Backing | 7mm |

| Total Carpet Thickness | 10mm |

| Total Carpet Weight | 2200g/m² |

| Backing Materials | Juteweft, 80% polyester / 20% cotton warp |

| Backing Finish | Environment friendly SBR latex, fray resistance compound |

Performance and Test Results

| a. Critical Radiation Flux (ASTME648) | class 1 |

| b. Tuft Bind (WNZ TM 202) | > 10N |

| c. Insect Resistance (WNZTM 27) | class 5 |

| d. Color Fastness Against Light (ISO 4892-2:1994) | > Class 4 |

| e. Electric Propensity (AATCC134) | < 3.5KV |

| f. Thickness Loss Under Static Loading (WNZTM124A) | Minimum 80% thickness recovery after 24 hours removal of load |

| g. Thickness Loss Under Dynamic Loading | 1000 impacts (GB/T14252-93) average rate of loss <15%loss <15% |

| h. Hexapod Appearance Change After 12000 Revolutions (WNZTM 247/251/284) | Min 3 |

| i. Immersion in Hot Water | Pass |

| j. Durability and Fiber Integrity (WNZTM283) | Average rate of loss of 30mg/1000cycles |

| k. Hot Metal Nut Test (BS4790) | Pass |

| l. Methanamine Table Test (BS6307) | Pass |

| m. Smoke Emission (ASTME 662) | Pass |

| n. Fire Load Density | 68.7 (MJ/M²) |

| o. Environmental | Pass the test of CRI indoor air quality program |

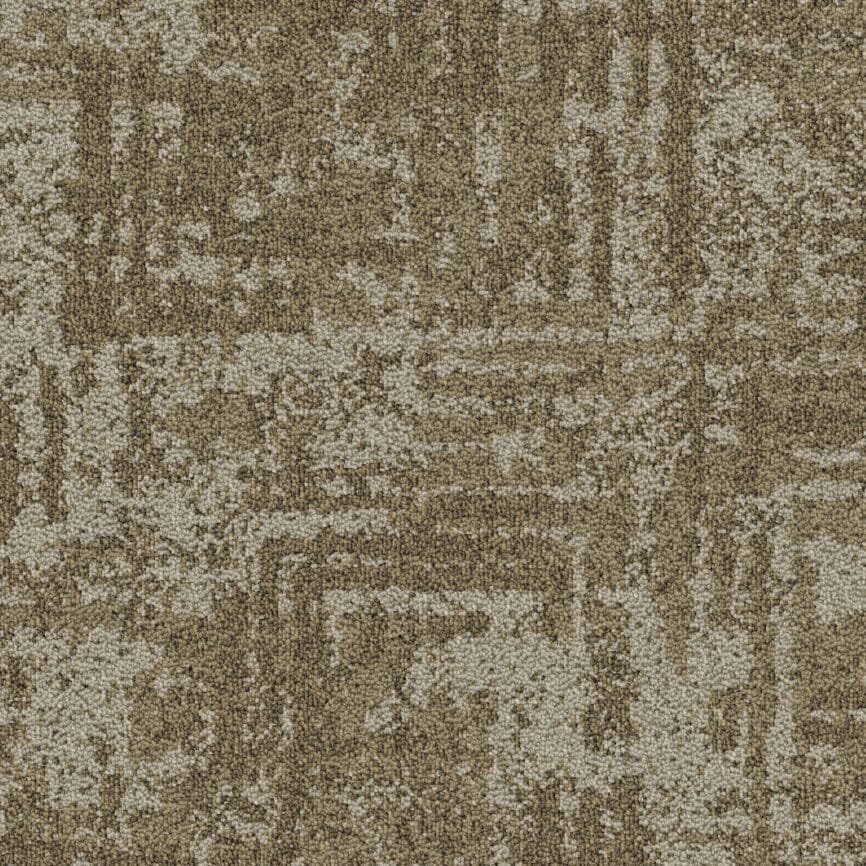

SPECIFICATIONS

| Function | Room |

| Construction | A genuine Woven Axminster |

| Pile Content | 80% Wool, 20% nylon |

| Yarn Count | R740/2 |

| Pitch | 7/inch(27.56/dm) |

| Rows/inch(Rows/Dm) | 7/inch(27.56/dm) |

| Tufted Density | 49/inch²(759.55/dm²) |

| Total Pile Weight | 1131g/m² |

| Pile Height Above Backing | 7mm |

| Total Carpet Thickness | 10mm |

| Total Carpet Weight | 2200g/m² |

| Backing Materials | Juteweft, 80% polyester / 20% cotton warp |

| Backing Finish | Environment friendly SBR latex, fray resistance compound |

Performance and Test Results

| a. Critical Radiation Flux (ASTME648) | class 1 |

| b. Tuft Bind (WNZ TM 202) | > 10N |

| c. Insect Resistance (WNZTM 27) | class 5 |

| d. Color Fastness Against Light (ISO 4892-2:1994) | > Class 4 |

| e. Electric Propensity (AATCC134) | < 3.5KV |

| f. Thickness Loss Under Static Loading (WNZTM124A) | Minimum 80% thickness recovery after 24 hours removal of load |

| g. Thickness Loss Under Dynamic Loading | 1000 impacts (GB/T14252-93) average rate of loss <15%loss <15% |

| h. Hexapod Appearance Change After 12000 Revolutions (WNZTM 247/251/284) | Min 3 |

| i. Immersion in Hot Water | Pass |

| j. Durability and Fiber Integrity (WNZTM283) | Average rate of loss of 30mg/1000cycles |

| k. Hot Metal Nut Test (BS4790) | Pass |

| l. Methanamine Table Test (BS6307) | Pass |

| m. Smoke Emission (ASTME 662) | Pass |

| n. Fire Load Density | 68.7 (MJ/M²) |

| o. Environmental | Pass the test of CRI indoor air quality program |